June 2025 - Welding Inspector Specialist Course

Congratulations to team members and inspectors Ana Castro and Greg Devine for exceeding all the expectations in the Welding Inspector Specialist Course AWS B5.2 given by The Welder Training and Testing Institute (WTTI).

Our fabrication team has always been experienced in maintaining tight tolerances and providing the craftsmanship needed for challenging parts. But that's not always enough in today's challenging DOD world and so we keep ahead of the latest stringent weld requirements.

September 2024 - Our new Haas VF6SS arrives

Our new Haas VF6SS CNC Vertical Machining Center features a 12,000 RPM Spindle, Exceptionally Fast Rapids & Tool Change, 30+1 Tool Capacity and 64 x 32 x 30 Travel. It's ready to offer our customers the versatility of a high speed machine and a large work envelop.

July 2024 - VMA is using PreVeil as part of our NIST-800-171 CUI Compliance

The DoD requires all defense contractors and organizations overseeing CUI to meet CMMC Level 3 compliance standards. Popular email and file-sharing systems are not compliant. Vantage Manufacturing & Assembly has chosen PreVeil’s Email and Drive solution because it’s simple, secure, and compliant technology solution will allow us to store and share CUI with our supply chain while keeping our existing email infrastructure in place.

June 2023 - VMA celebrates our 20 year anniversary

VMA is proud to be a single source for your complete product production. We remain one of the few Contract Manufacturers left in our area who can still do it all under one roof. We continue to offer: Mechanical design support, Sheetmetal Fabrication, Welding, Milling, Turning, PCB Assembly, Cable Assembly, Box Build, Turnkey Product, System Integration, Test, Packaging, and delivery to your door.

September 2021 - New Doosan Vertical Mill Arrives

We've added a Doosan DNM 750L II, with a 80" table for large precision milling operation. This augments our current compliment of milling stations and adds more capacity.

March 2020 - VMA Remains Open

The recently issued Stay At Home Order for NYS will not affect the normal hours or operations of Vantage Manufacturing & Assembly. Your key contacts will remain the same although those who are able to work from home will be doing so. Be safe everyone.

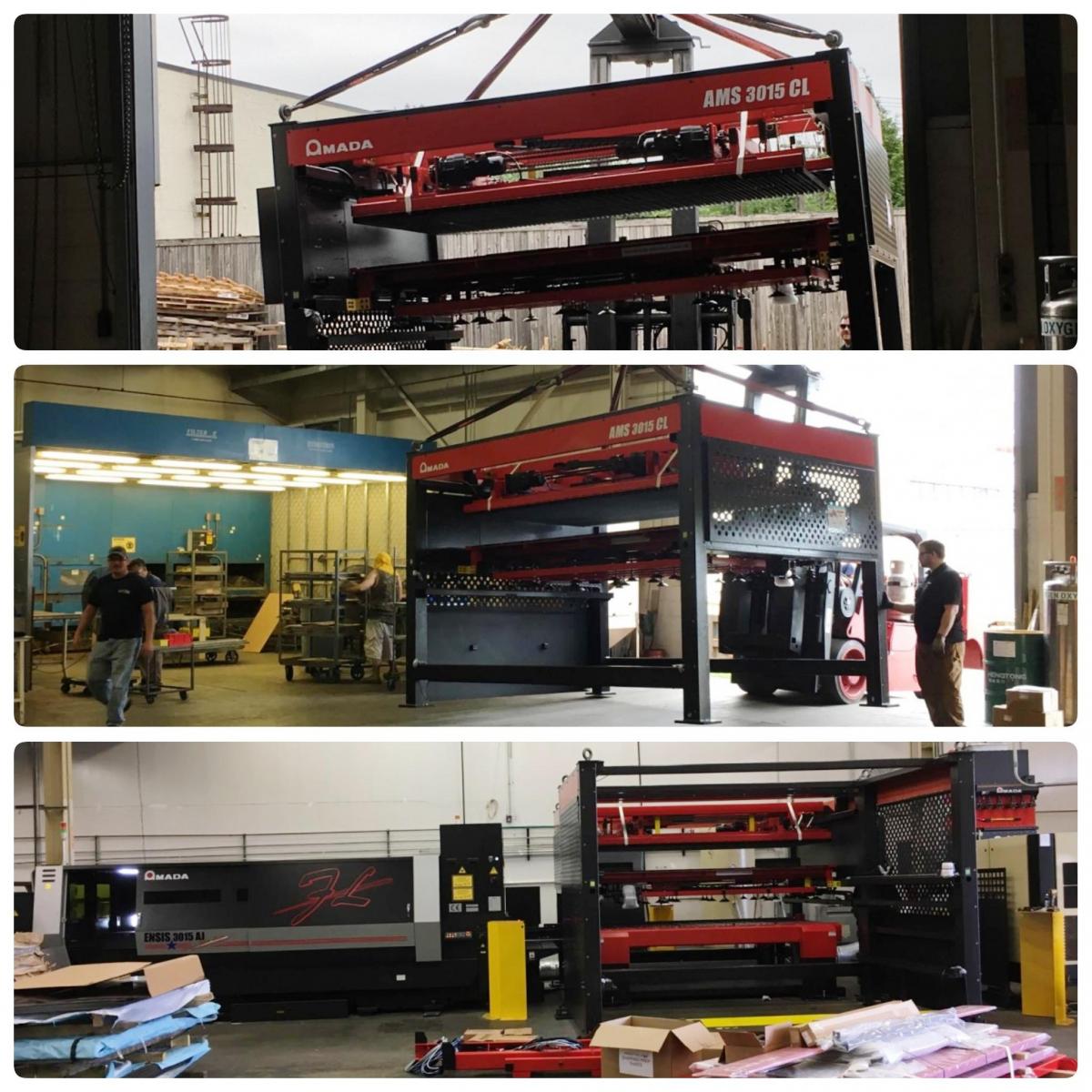

June 2019

To complement our Amada ENSIS 3KW 3015 Fiber Laser it’s modular automated loader just arrived.

April 2019

VMA is exhibiting at the Design-2-Part show in Uncasville, CT at the Mohegan Sun Exposition Center on April 24th and 25th. The Exposition Center is located at 1 Mohegan Sun Boulevard, Uncasville CT, and the show is the region’s largest contract manufacturing trade show. Show hours are 9:30-4:00 on the 24th and 9:30-3:00 on the 25th. Come visit us in booth 315!

March 2019

VMA purchases our new Amada ENSIS 3KW 3015 Fiber Laser with proprietary fiber laser technology. We can process both thin and thick materials at high speeds. Stay tuned for the savings we can pass along to you!

February 2019

VMA installs our new Doosan DNM 5700 vertical machining center. We're very happy with this machine

July 2018

VMA is pleased to announce our 15th anniversary.

April 18th & 19th 2018

VMA will be exhibiting in the Design 2 Part show at the Meadowlands Exposition Center in Secaucus, NJ on Weds April 18th and Thursday April 19th. This show is for those seeking contract manufacturing services or for anyone wanting to keep up with local manufacturing technology. Show hours are 9:30-3:30 on Weds and 9:30-3:00 on Thursday.

Come visit us in booth 430!

For more information on the show see the link below:

https://www.d2p.com/2018-meadowlands-manufacturing-trade-show

March 2018

The Grand Island New York cashless toll Installation went live on 3/30/18,

with VMA’s electronic panel assemblies in place.

December 2017

VMA installs our N2 Microbulk to feed nitrogen to our CNC Laser

.

August 2017

Beginning with crude photos and notes, VMA creates a working 3D model and ultimately produces the end product. These are custom fabricated battery gate cart weldments for one of our new customers in the Material Handling Industry.

May 2017

VMA passes our ISO 9001:2008 re-certification audit again with ZERO non-conformities.

June 2016

Visit VMA in booth 412 at the Atlantic Design & Manufacturing Show (Jacob Javits Center - NYC) June 14th to June 16th.

January 2016

VMA manufactures and supports the Power Supply Assemblies and other electronics behind Steinway's most significant product innovation in over 70 years. We ship to both their Hamburg Germany and Astoria NY plants.

The innovation is "The Spirio"... The world's finest player piano system. It's not just a player piano... It's having the heart & soul of the artist in your living room.

The software coupled with clever mechanical engineering provides the most accurate reproduction of live performances ever achieved on any piano. Delicate pedaling, subtle phrasing, soft trills, and thundering fortissimos present no difficulty for our Steinway Spirio.

July 2015

VMA's sister compamy, EAW Electronic Systems, Inc., is on the verge of introducing an innovative building automation system. The new technology, called an EMC 20/20, is used to control a building's heating, ventilation, and air conditioning (HVAC) system, and will support industry standard Communication. The prototype shown below has already evolved and is getting ready for full production.

November 2014

VMA ordered the Mazak VERTICAL TRAVELING COLUMN (VTC) 800/30 SR Vertical Machining Center. Delivery of the machine is planned for February, and our team is excited to offer our customers the increased capabilities and efficiencies.

It features a high speed 40 Taper spindle, swivel spindle head (B Axis), full traveling column design and fixed table for machining of extremely long and heavy workpieces. With the optional table partition, the long machine table can be transformed into two separate work areas, with smaller and 5 axis parts run accurately and cost effectively. The Roller Gear Cam design swivel head delivers improved accuracy and repeatability due to the backlash free design, which allows the machining of complex features and contours. These features offer excellent machining capacity for a large variety of work pieces. A significant reduction of machining processes and increased productivity can be realized thanks to the additional axis, and when combined with the rotary table, full 5-axis simultaneous machining will soon be a service that VMA can provide. The machine also delivers fast rapid traverse rates to reduce non-cut times.

MACHINE CHARACTERISTICS:

· 18,000 RPM 40 Taper Spindle

· Swivel Spindle Head (B Axis +/- 110 degrees)

· 48 Tool Magazine

· Full 5 axis contouring

· Table Center Partition-OPT

· Max Table Load 5,500 lb

November 2014

VMA has purchased the Haeger 824 OneTouch 4e lite Press. It features easy and fast changeover with automatic fastener loading. Most important to VMA; it has automatic detection for proper insert length and location.

VMA adds a Customer Satisfaction Survey to our website. Our customers are important to us and we like to know how we're doing. So we've just installed a very user friendly 'Customer Satisfaction Survey' to our website. We want to hear it all (good and bad), because that's how we continuously improve.

The entire VMA management team began a Value Stream Mapping refresher course as part of our continuous improvement efforts. In our Quality Objectives, we are committed to meeting on-time delivery to our customers. Over the weeks, the team developed an up-to-date, “current state” map of our entire process flow. Then, using the current state map, we derived a future state map, which will be used to identify potential improvements and breakthrough opportunities.